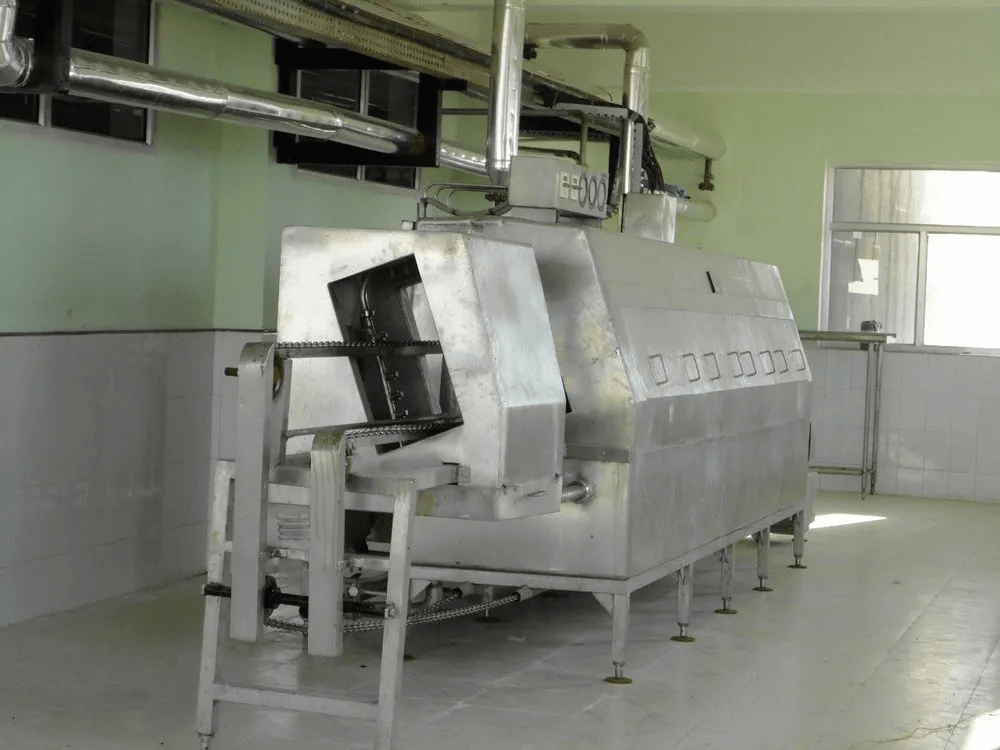

Crate Washer

Unique washing principle allows products to be washed in crates or totes. The whole heads or whole leaves are placed in crates/totes and are transported through the washer by a chain. Each crate/tote may be loaded with a different product and fed sequentially through the washer.

Crate Washer

Unique washing principle allows products to be washed in crates or totes. The whole heads or whole leaves are placed in crates/totes and are transported through the washer by a chain. Each crate/tote may be loaded with a different product and fed sequentially through the washer.

FEATURES & BENEFITS

- Optimal washing results for all kinds of different products including whole head and whole leaves

- Different crates/totes can be used

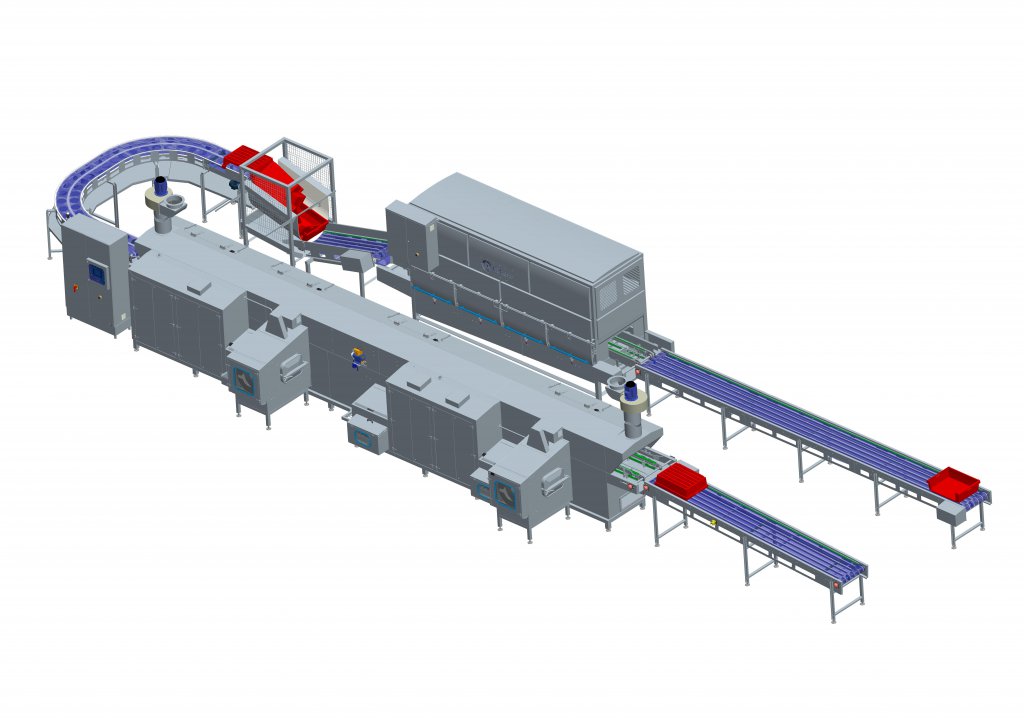

- System can be made completely automatic with crate/tote handling systems

- Easy to operate and clean

DETAILS

- Able to wash different crate sizes

- Consistent washing of crates

- Hygienic design

OPTIONS & MODELS

- Options

- Stainless steel plate with large holes

- Automatic infeed and outfeed

- Automatic electric valve for fresh water spraying pipe

- Cooling coil

- Automatic filling valve

ADVANTAGES OF CRATE WASHING MACHINE

Product Features

Using a Crate washing machine offers several advantages, which is especially true in businesses with stringent hygiene regulations, such as the food industry. A Crate Washing Machine can be used in a variety of industries.

Crates, Pallets, Trays, and other similar items must be cleaned after each usage. You can do it manually with a high-pressure washer, but it takes a long time, a lot of water, and a lot of energy. Using a Crate Washing Machine allows you to automate this operation, making you more efficient.

Water and energy usage are lowered, and cleaning time is cut. In comparison to a manual option, a crate washing machine will provide better and more consistent cleaning.

You can pick between manual or automated crates infeed and outfeed when purchasing a crate washing machine. This is frequently determined by the number of crates to be cleaned. The crate washing machine may be supplied with a one-person operation system if manual infeed and outfeed of crates are chosen. The crates’ entry and exit locations are both on the same side of the machine in this example.

The washing Machine is completely manufactured and certified in line with the strictest hygiene and safety criteria, ensuring, for example, food safety. A Crate washing machine may be quickly cleaned and operates with high reliability. This is a relatively minor system maintenance cost.

A Crate washing machine comes standard with at least one wash zone and one rinse zone. The rinsing zone’s hot water is filtered and kept at the proper temperature before being utilized in the washing zone. Our machines’ water and energy usage are maintained to a minimum thanks to this recovery mechanism.

Crate washing machines enable great cleaning performance, ensuring compliance and crate hygiene without jeopardizing long-term sustainability. Crate washing machines are also incredibly adaptable, with their tiny design allowing them to better adapt to diverse line layouts, for example. Dirt on the boxes detracts greatly from sales performance at the point of sale.

The Crate Washing Machine, on the other hand, will draw favorable attention to your items since it cleans drinks crates and other plastic packaging thoroughly and gently. The new washer is distinguished by its modular design and increased washing capacity, which is compatible with a variety of box designs.

The new technology is included inside the Crate washing machine and has a 10-inch touchscreen with a 2.5-fold increase in screen space. All operational data is therefore accessible at a glance. So, if you work in a business where clean items have a high value and boost product market value, you should utilize a Crate washing machine. One may improve the quality of their products and boost their worth by using this equipment.

DIFFERENT ZONES MAKE UP THE CRATE WASHING MACHINE:

Spray nozzles in the pre-wash zone clean the crates at a lower water temperature, eliminating blood and protein residues. Spray nozzles in the main wash zone and clean the boxes with extremely hot water. All contaminants are eliminated with the help of the right chemicals.

STICKER REMOVAL

High-pressure dirt killers are used to remove stickers and adhesives from containers. The crate is treated on all four sides. A little microfilter removes minute particles from the water.

RINSE ZONE

Crates washing machines are rinsed with new cold or hot water to eliminate any remaining detergent. The crates dry faster when they are washed in hot water. The rinse water in crate washers is meant to be reused. Stainless steel fans blast hot air through the containers in the Blow-off Unit Zone. Because the air is heated via circulation, it is more energy efficient and has a greater blowing capacity.

- ENERGY SOURCES USED WISELY

It’s a pity if a lot of heat is generated in your company process and then taken away unused. By including a heat exchanger in the crate washing machine, residual heat from the business process may be used to heat the crate washing machine’s washing water.

- EXTERIOR WALLS THAT ARE INSULATED

A Crate washing machine outside walls and water tanks can be insulated if desired. As a result, less heat is lost by radiation. Less energy is required through better heat retention in the system. If the crate washing machine has a steam suction system, heat is collected throughout the operation. As a result, energy losses are significantly reduced.

- FUNCTION OF STAND-BYS

It’s a pity to waste water and energy when no crates are being washed in the crate washing machine, yet it’s still running. As a result, the crate washing machine has a standby mode. A sensor in the rinsing arch triggers this. When this sensor detects no crates for a period of time, the rinsing arch is turned off and the washing pumps are turned off.

The operation is automatically repeated as soon as the crates are placed back into the washer. Before the washer goes into standby, you can set the time yourself. Of course, the shorter this period is, the less water and energy are lost.